Our company offers custom CNC milling and turning parts in materials like aluminum, stainless steel, and steel. Our precision metal

machining services cater to various industries and can create intricate designs according to your requirements. Materials and

structures for which we are good at.

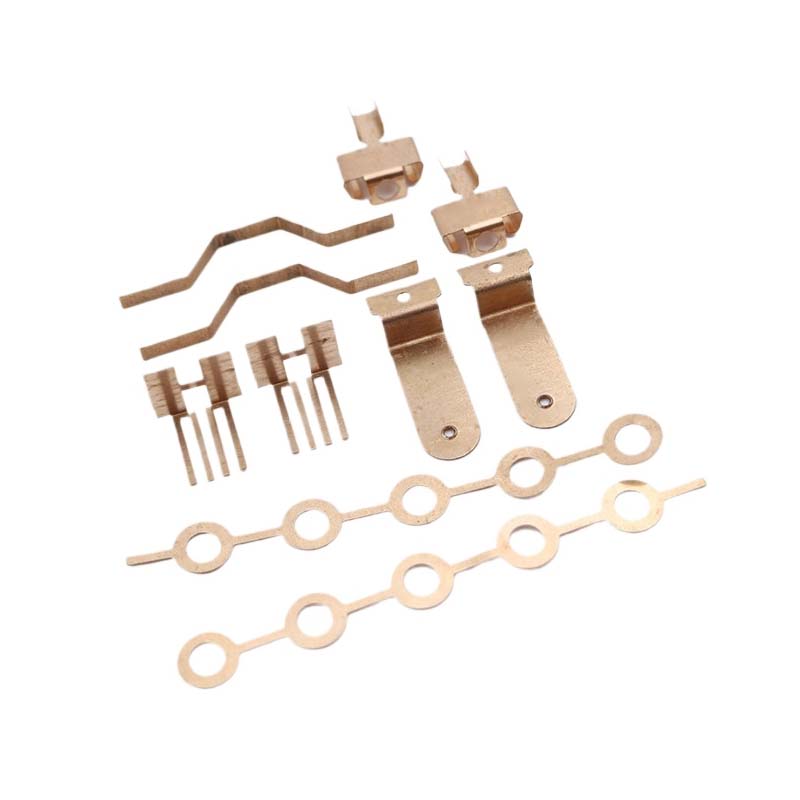

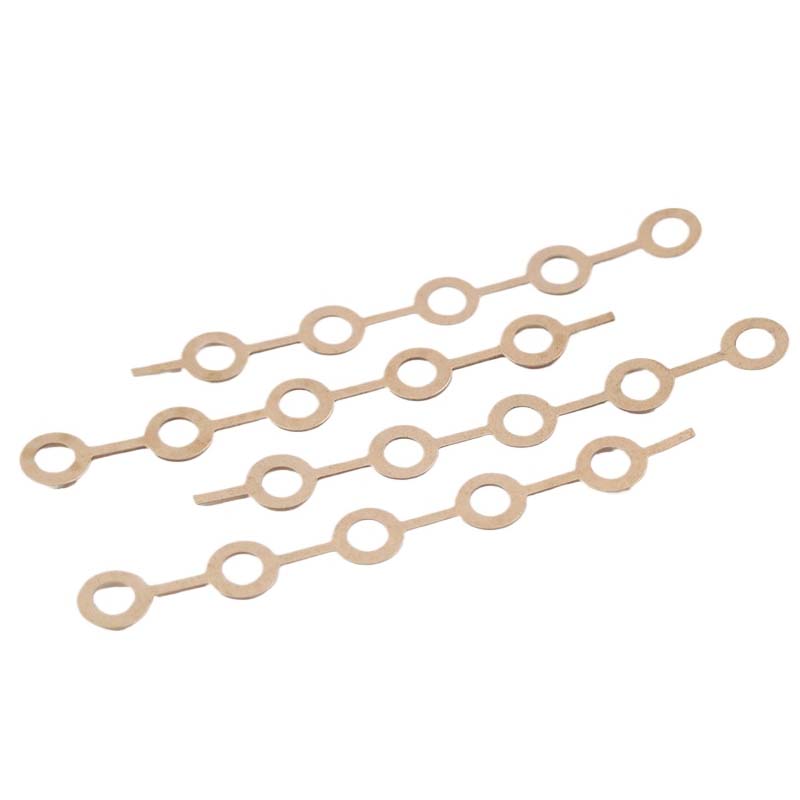

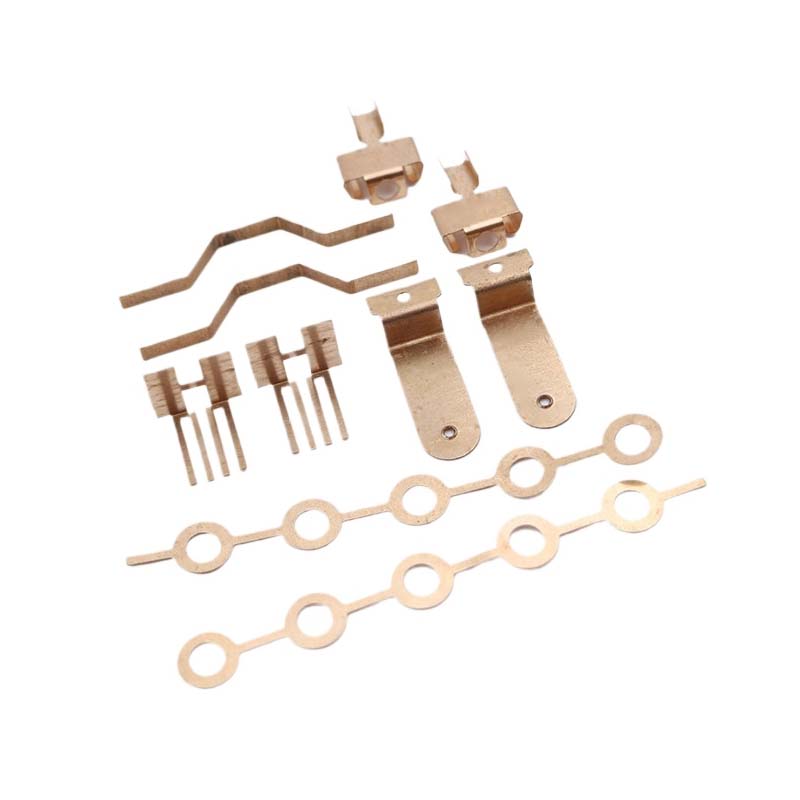

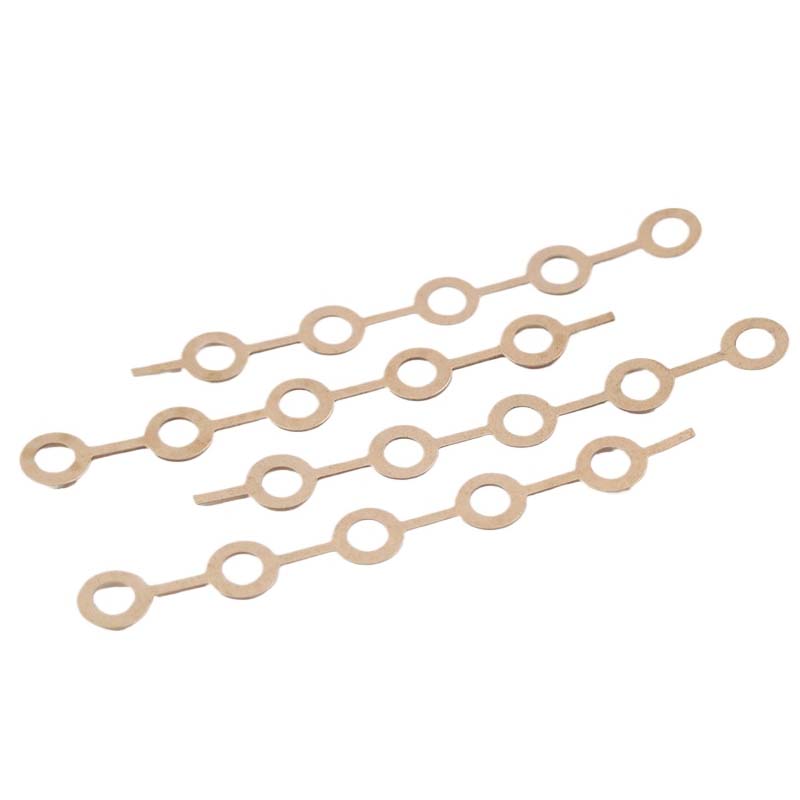

Product Case

Our Advantages

| Our Advantages |

13+ years of production experience |

| The MOQ is 1 piece |

| Rapid prototyping |

| 2μm machining accuracy |

| CNC customized machining service |

Process Introduction

CNC Turning:

The workpiece rotates and the cutting tool moves in a straight or curved line in a plane during cutting. Turning is generally used

to machine the inner and outer cylindrical surfaces, end faces, conical surfaces, forming surfaces, and threads of workpieces.

CNC Milling:

Using rotating multi blade cutting tools to cut workpieces, suitable for machining flat surfaces, grooves, various forming

surfaces (such as flower keys, gears, and threads), and special forming surfaces of molds, etc.

CNC Planing:

The cutting method of using a planer to perform horizontal relative linear reciprocating motion on a workpiece is mainly used for

the shape machining of parts.

CNC Grinding:

By using high-speed rotating grinding wheels or discs to grind workpieces, it is suitable for high-precision and smooth surface machining

and grinding, which can achieve very high dimensional accuracy and low surface roughness.

CNC Drilling:

The process of using a drill bit to process holes in solid materials, usually done on a drilling machine or lathe.

CNC Boring:

By using a boring tool to cut workpieces, it is suitable for machining larger and deeper holes. Boring can achieve high dimensional accuracy

and low surface roughness.

About Us

FAQ

Q1: How Can I Get Aluminum Parts Sample?

A: Sample of your own design need to pay for the production set up charge. Sample production takes 5-7 working days after charge recevied and size drawing approval.

Q2: What is The Process Of an Order?

A: Send your detailed request→Feedback with quotation→confirm quotation and make payment→Make size drawing for approval→Make production→Production test→Sample test(approval)→Mass production→Quality checking→Delivery→After service→Repeat order.

Q3: Why Should You Buy from Us Not from Others?

A: 13 years of focus on high-precision prototype manufacturing field.

we are committed to meet the different needs of different customers, for customers efficient supply of qualified products.

Q4:Can You Give Me Help If My Products are Very Urgent?

A:Yes, of course. We will try our best to give you help. Because we have our own factory to produce. We can flexible to adjust our production schedule.

If You Are Inerested in Our Products, Please Feel Free to Contact Us!

SUBSCRIBE TO OUR NEWSLETTER

SUBSCRIBE TO OUR NEWSLETTER