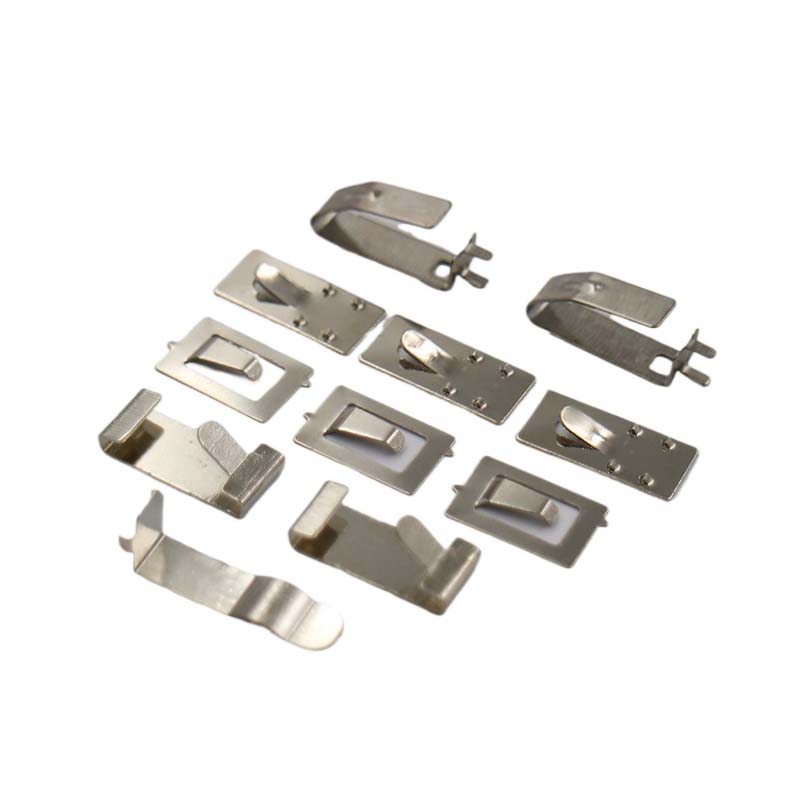

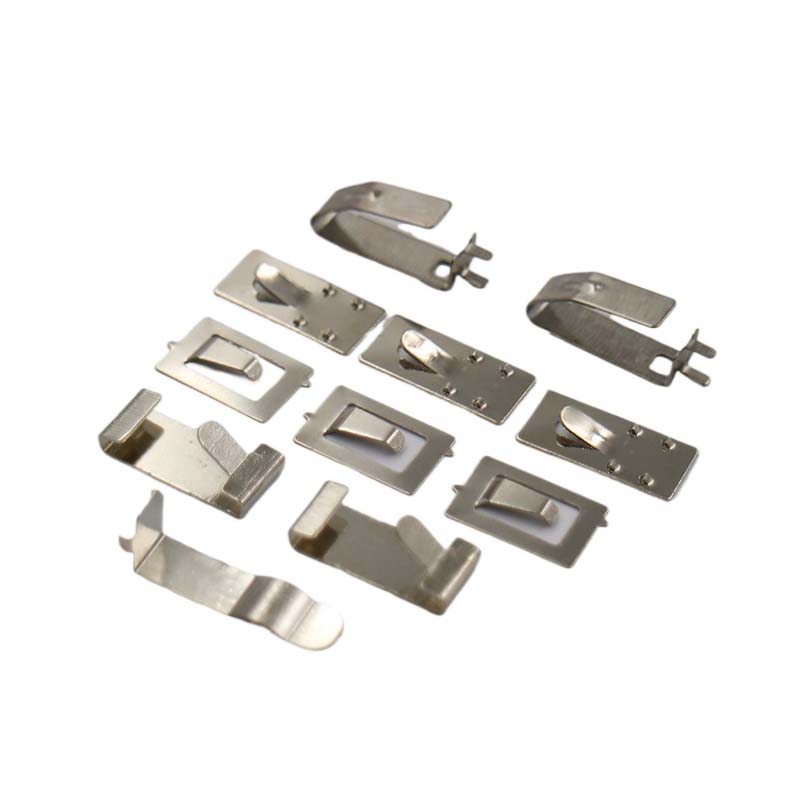

Product Details

| Key word |

CNC Custom Maching Parts |

| Color |

As per your requirements |

| Tolerance |

As per your requirements |

| Surface Roughness |

As per your requirements |

| Size |

As per your requirements |

Product Images

Material

| Aluminum alloy |

7075,LY12,6063,6061,5052,1060... |

| Copper |

H62,H59,H60,QBe2.5,Qsn6.5,T1,T2... |

| Plastics |

PEEK,POM,PTFE... |

| Stainless steel |

17-4,440C,9Cr18,316L,321... |

| You can specify |

surface Treatment

Common surface treatment methods include anodizing, polishing, sanding, laser, heat treatment, etc. We have extensive experience in surface treatment.

You can tell us the type you need, and we will present you with the best product.

Processing Type

- TurningThe workpiece rotates and the cutting tool moves in a straight or curved line in a plane during cutting. Turning is generally used to machine the inner and outer cylindrical surfaces, end faces, conical surfaces, forming surfaces, and threads of workpieces.

- MillingUsing rotating multi blade cutting tools to cut workpieces, suitable for machining flat surfaces, grooves, various forming surfaces (such as flower keys, gears, and threads), and special forming surfaces of molds, etc

- PlaningThe cutting method of using a planer to perform horizontal relative linear reciprocating motion on a workpiece is mainly used for the shape machining of parts.

- GrindingBy using high-speed rotating grinding wheels or discs to grind workpieces, it is suitable for high-precision and smooth surface machining and grinding, which can achieve very high dimensional accuracy and low surface roughness.

- DrillingThe machining method of using a drill bit to drill holes on workpieces is suitable for drilling operations on various materials.The accuracy and efficiency of drilling depend on the quality and operational techniques of the drill bit.

- BoringBy using a boring tool to cut workpieces, it is suitable for machining larger and deeper holes. Boring can achieve high dimensional accuracy and low surface roughness,

Company Introduction

Company Certification

FAQ

1. who are we?

We are based in Anhui, China, start from 2024,sell to North America(60.00%),Western Europe(30.00%),Eastern Europe(10.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

CNC Precision Parts, Aeronautical Parts, Medical Equipment Parts, Automotive Parts, CNC Milling Parts

4. why should you buy from us not from other suppliers?

13 years of focus on high-precision prototype manufacturing field.

we are committed to meet the different needs of different customers, for customers efficient supply of qualified products.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Spanish,Japanese,French

SUBSCRIBE TO OUR NEWSLETTER

SUBSCRIBE TO OUR NEWSLETTER