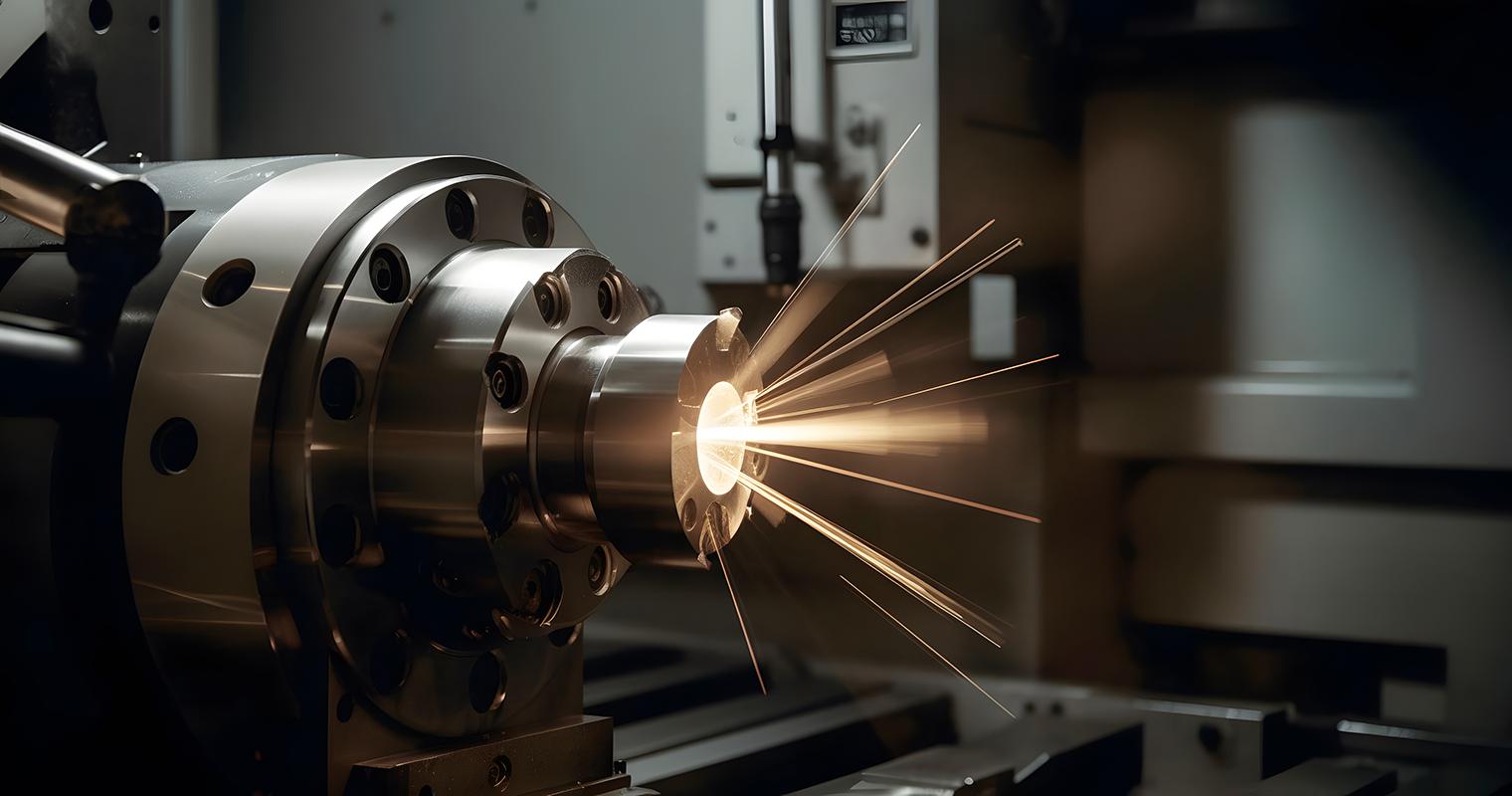

CNC Milling Processing

Our CNC milling services can produce highly accurate and

complex parts from a variety of materials, including metals

plastics,and composites.

Machinery Axis: 3,4,5,6

Tolerance:+/- 0.05mm

Special Areas :+/-0.002mm

Surface Roughness: Ra0.1~3.2

Supply Ability:300000Piece/Month

CNC Turning Processing

OEM&ODM

Customized Precision Parts

1-Piece minimum order

3-Hour quotation Samples: 1-3 Days

Lead time: 7-14 Days.

QC team, inspection

report Guarantee

Lifetime After-Sales Service

Certificate:Medical,Aviation,Automobie,

ISO13485, IS09001, GB/T9001, GJB9001C

Our Service

We are proud to hold several production certificates for our CNC machining services,which demonstrates our commitment to quality and customer satisfaction. Our team follows strict quality control procedures to ensure that every part we produce meets the highest standards of quality and accuracy.

| Processing |

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM). |

| Material |

Aluminum: 2000 series, 6000 series, 7075, LY12 , 6063, 6061, 1060, 5052, etc. |

| Stainlesss steel: SUS303, SUS304, 321,SS316, SS316L, 17-4PH, 440C, 9Cr18. |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, QBE2.5, Qsn6.5, T1, T2, Bronze, Copper |

|

Titanium: Grade F1-F5

|

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| Surface Treatment |

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated,Passivation, Electrophoresis, Electro Polishing, Knurl, Nano matte coating,Laser/Etch/Engrave, Medical inactivation etc. |

| Tolerance |

±0.05 ~ ±0.002mm |

| Surace Roughness |

Min Ra 0.1~3.2 |

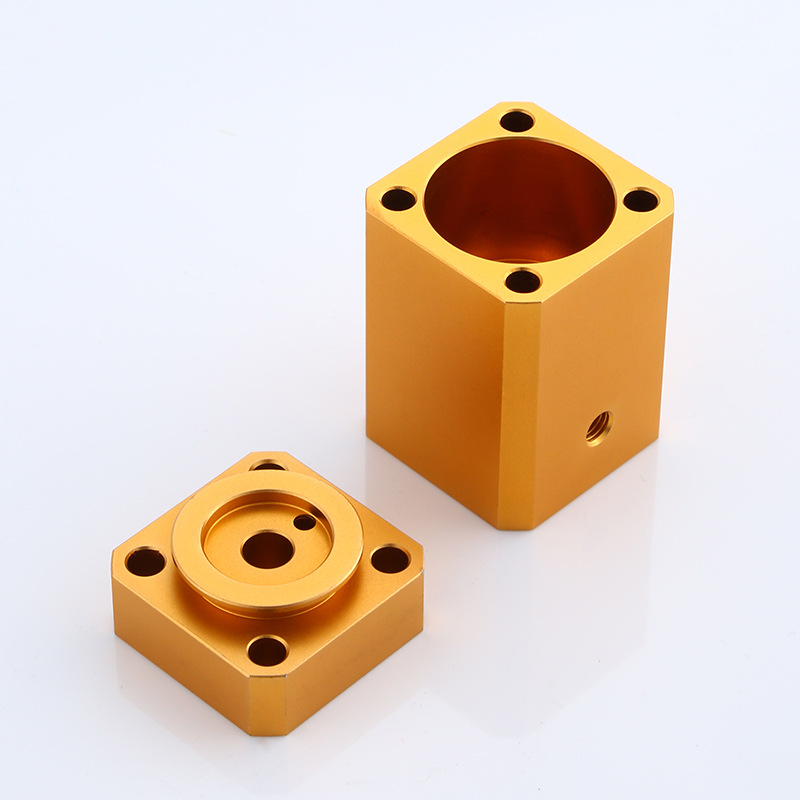

Product Display

Aluminum

Tolerance: +/- 0.01~+/-0.002mm

Material:2024, 5083, 6061, 6063, 7075, etc.

Surface treatment: Oxidation, electrophoresis,sandblasting, electroplating, chemical treatment, painting, hard anodizing.

Stainless Steel/Steel/Titanium Alloy

Tolerance: +/- 0.01~+/-0.005mm

Material:SUS303, SUS304, SS316, SS316L,17-4PH, etc.

1214L/1215/1045/4140/SCM440/40CrMo, etc.

TA1,TA2/GR2, TA4/GR5, TC4, TC16,TC18,TC21,TC22,TC26,TC118B etc.

Surface treatment: Electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivation, heat treatment.

Brass/Copper

Tolerance: +/- 0.01~+/-0.002mm

Material: HPb63, HPb62, HPb61, HPb59, H59,H68, H80, H90, C11000, C12000, C22000, C26000, C28000, C36000 etc.

Surface treatment:Electroplating, tin plating, spraying, oxidation, polishing, spray grinding, heat treatment,pickling, shot peening,etc.

Surface Treatment

Company Profile

We are engaged in precision CNC turning, grinding, inserting, milling, EDM process. Our products are mainly used for industrial, medical, oil, optical, remote sensing mapping, semiconductor, aerospace, military, automotiveIn fields.We import our machines from USA and Japan. The minimum tolerance we can make is 0.002-0.05mm. Independent research and development of CRM,MES,APS system, and achieve artificial intelligent factory. Our workers are trained and follow ISO standard.

FAQ

Q1: How Can I Get Aluminum Parts Sample?

A: Sample of your own design need to pay for the production set up charge. Sample production takes 5-7 working days after charge recevied and size drawing approval.

Q2: What is The Process Of an Order?

A: Send your detailed request→Feedback with quotation→confirm quotation and make payment→Make size drawing for approval→Make production→Production test→Sample test(approval)→Mass production→Quality checking→Delivery→After service→Repeat order.

Q3: Why Should You Buy from Us Not from Others?

A: 13 years of focus on high-precision prototype manufacturing field. we are committed to meet the different needs of different customers, for customers efficient supply of qualified products.

Q4:Can You Give Me Help If My Products are Very Urgent?

A:Yes, of course. We will try our best to give you help. Because we have our own factory to produce. We can flexible to adjust our production schedule.

If You Are Inerested in Our Products, Please Feel Free to Contact Us!

SUBSCRIBE TO OUR NEWSLETTER

SUBSCRIBE TO OUR NEWSLETTER