CNC machining has undergone remarkable technological advancements throughout its history, transitioning from basic programming methods like punch tape to advanced software and high-speed, multi-axis machines. However, the recent emergence of Artificial Intelligence (AI) has introduced a new dimension to the field, offering the potential for further innovation and progress.

In this blog post, we will explore the role of AI in CNC machining in greater detail, examining its current utilization, future prospects, and the associated challenges. Additionally, we will investigate how various types of CNC machine shops are adopting AI and the broader impact it is having the industry.

The Impact of AI on CNC Manufacturing

Uninterrupted Production

AI's impact on CNC manufacturing is seen in its ability to enable uninterrupted production. AI-driven robots can work continuously, 24/7, without the need for breaks or downtime. This is particularly advantageous for mass production and large manufacturing units, ensuring a consistent pace of production and faster delivery times.

Enhanced Safety Measures

Safety is a top priority in manufacturing environments, and AI contributes to safer workplaces by taking over hazardous tasks. Through machine learning and deep learning systems, machines can handle risky operations without human involvement. This reduces the risk of accidents and injuries while allowing human workers to focus on tasks that require critical thinking and creativity.

Streamlined Automation

AI and machine learning excel in automating repetitive and error-prone tasks. By utilizing AI, manufacturers can achieve greater efficiency and consistency in production. This streamlined automation helps maintain production consistency and reduces the likelihood of errors that result in waste or rework.

Growing Demand

The integration of AI into CNC machining has led to an increased demand for this manufacturing method. As AI and machine learning continue to enhance the quality, precision, and overall performance of CNC machining, more industries recognize its potential. Automotive, medical, aerospace, and marine sectors, among others, are increasingly relying on CNC machining for its efficiency and effectiveness. This rising demand for CNC machining is expected to persist as AI technology advances.

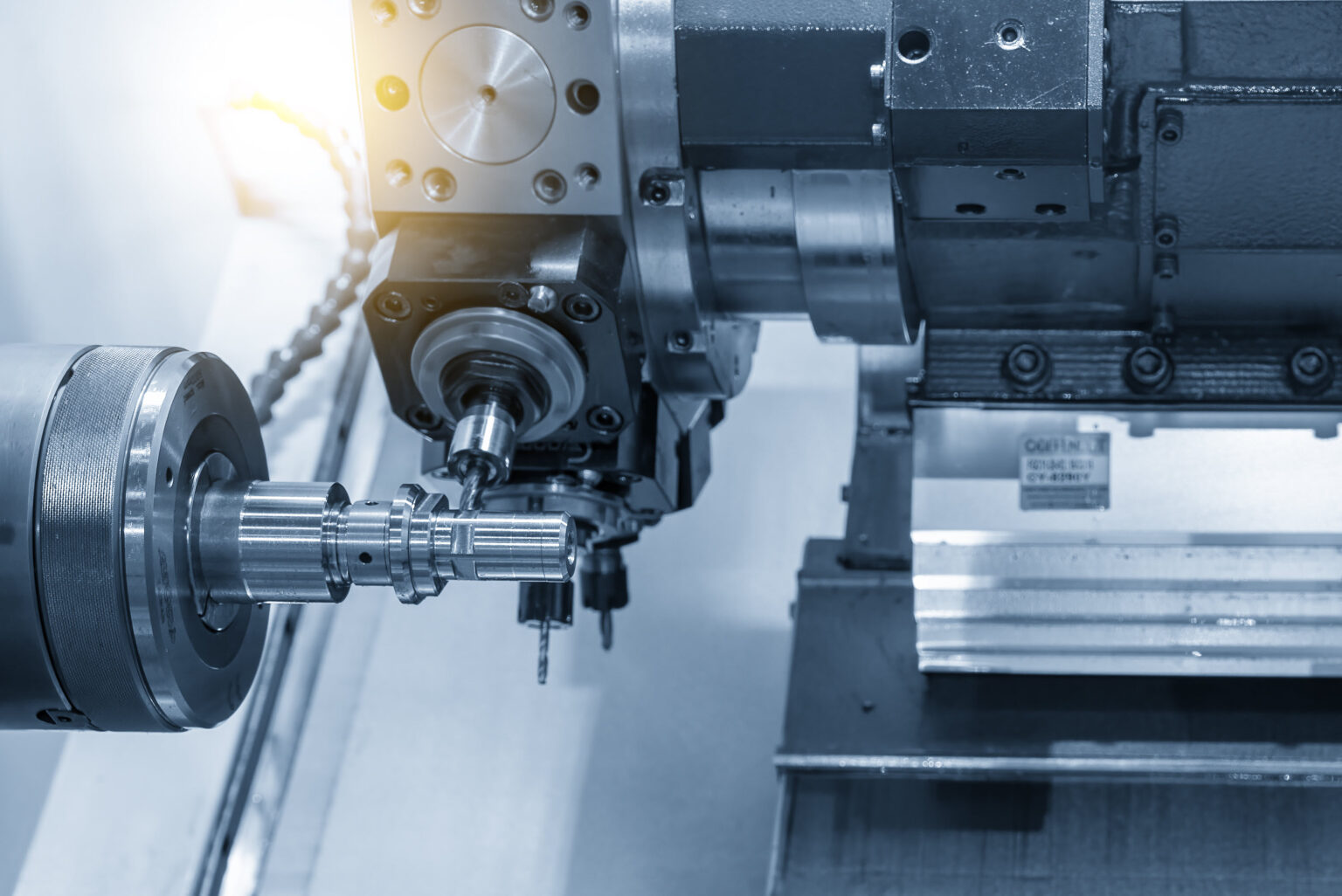

AI-Powered Tools and Machines

One of the key areas where AI is making its presence known in CNC machining is through the development of AI-powered tools and machines. These cutting-edge innovations leverage AI algorithms and machine learning techniques to enhance precision, productivity, and operational efficiency. By analyzing and interpreting vast amounts of data, AI machines can optimize cutting paths, adjust parameters on the fly, and minimize errors, resulting in faster, more accurate machining processes.

Processing Large Data Sets

CNC machining involves handling large amounts of data, ranging from design blueprints to real-time sensor readings. AI brings unmatched capabilities to efficiently process and derive insights from these data sets. With AI algorithms, manufacturers can tackle complex tasks such as predictive maintenance, quality control, and process optimization. By continuously learning from data, AI systems can identify patterns, detect anomalies, and make proactive decisions, enabling manufacturers to optimize their operations and reduce downtime.

The Future of CNC Machining with AI

The integration of AI with CNC machining holds tremendous promise for the future. As AI technologies advance, we can expect even more sophisticated solutions that push the boundaries of what is possible in CNC manufacturing. AI-powered autonomous machines capable of self-optimizing, self-calibrating, and self-repairing will revolutionize the industry. Additionally, the combination of AI with other emerging technologies such as Internet of Things (IoT) and Augmented Reality (AR) will further enhance the capabilities of CNC machining, enabling real-time monitoring, remote control, and immersive training experiences.

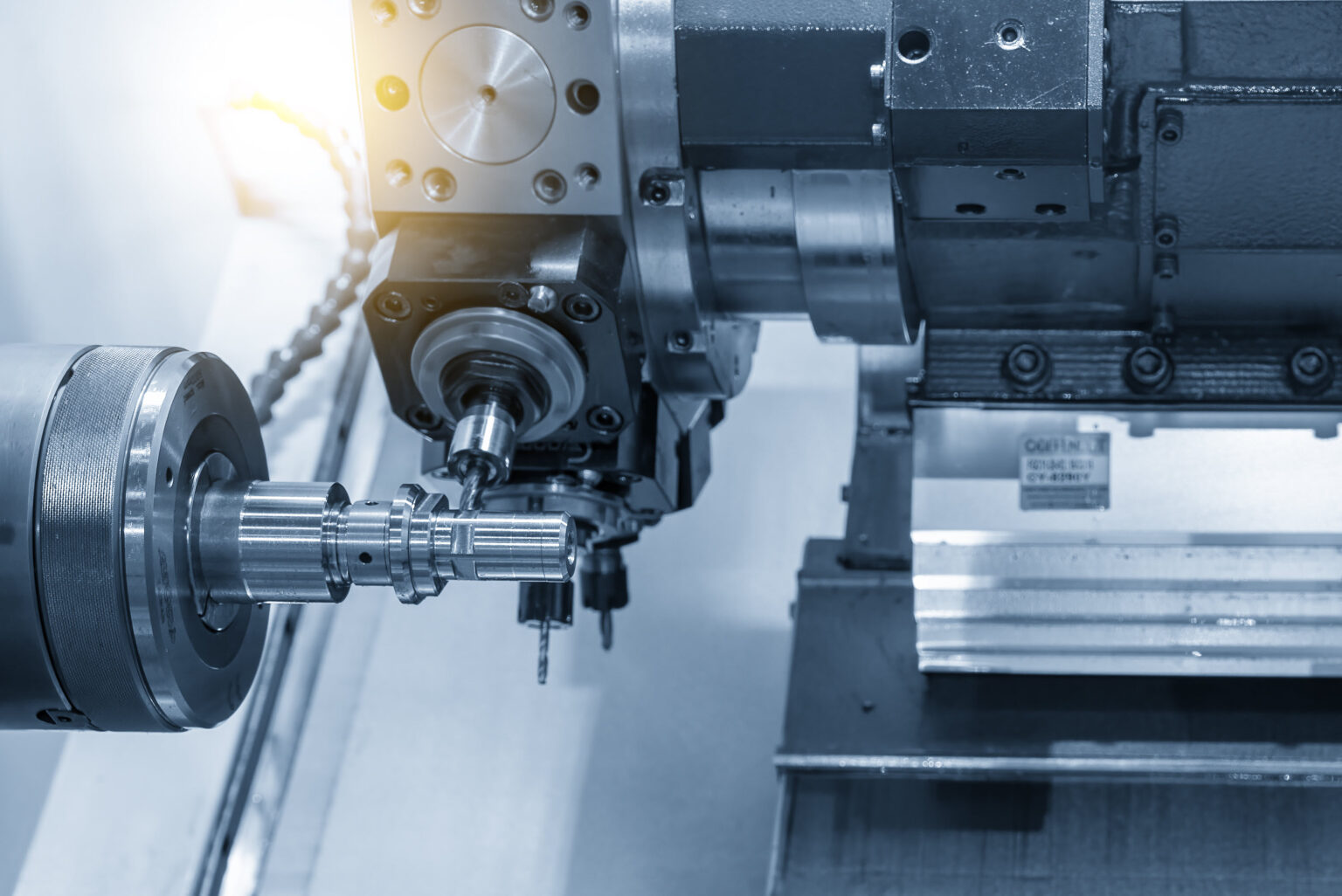

About Safekeso Precision Machining

The development of CNC machining has revolutionized the manufacturing industry, and the demand for CNC machines continues to grow. Safekeso stands out as a leading brand in the CNC industry, thanks to their commitment to quality, precision, and customer satisfaction. With their advanced facilities, expertise, and exceptional service, Safekeso is well-equipped to meet the high demands of custom CNC machining projects. Choose Safekeso for your CNC machining needs, and experience the advantages of their brand and superior products firsthand.

SUBSCRIBE TO OUR NEWSLETTER

SUBSCRIBE TO OUR NEWSLETTER